Inventory Department Procedures Manual

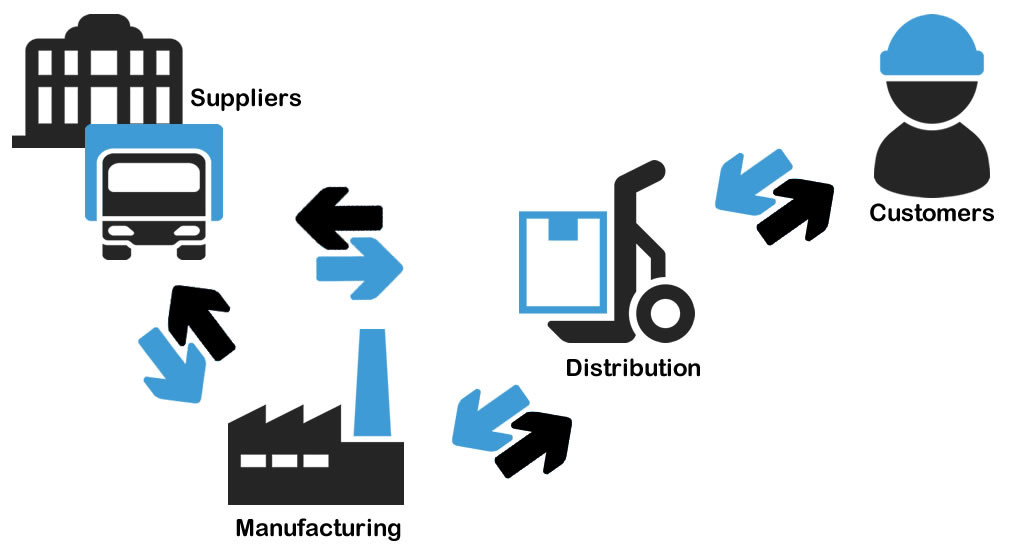

Receiving Goods and Supplies Inventory control begins immediately when orders enter your receiving department. Receiving personnel begin the documentation trail for each item that is received. The responsible person must make a visual inspection of every item in each shipment. Any item that is damaged or any order that does not match the bill-of-lading should be refused.

It is essential to properly document shipping orders when items are broken or incomplete. Remember, receiving is the gateway into your facility, so it is important to inspect and document every item that moves through shipping and passes into your storage facility. Stprage and Control Each product that comes into your storage facility has specific storage requirements. Some products must be kept at certain temperatures, some must be rotated to ensure timely shipment and some come with environmental requirements. Your tracking system should reflect each of these requirements and should prompt workers to monitor inventory for rotation requirements. Deficient storage methods expose your inventory to waste through expiration or inappropriate storage.

Inventory Control: Policies and Procedures Manual. The purpose of this manual is to establish procedures for the management and accountability of. Accounting Policies and Procedures for Early Stage. Department who is not.

Yamaha virago 250 user manual. Your storage should be organized so each item is clearly visible and storage requirements are clearly identified. Scheduling and Rotation Establish inspection dates for every item in your facility. Inspect for expiration dates, and make sure the oldest items are picked to fill shipping orders each and every time. Any item that is expired must be disposed of and documented to show the loss. Schedule physical inspections that require workers to touch every item in the warehouse. Any shortfalls must be justified and documented as a loss in your inventory control system.

Ultimately, employees who are found negligent must be held responsible for inventory loss. Product Shipping Eventually, every item in your inventory will leave the facility through the shipping department or through direct retail sale to customers. Shipped products must be properly removed from inventory.

Inventory Management Procedure Manual

This is an area of potential loss if an employee allows more product to leave the facility than is specifically ordered by a customer. Shipping personnel are key to your company's profitability. Products sold directly to retail customers must be removed from your inventory in a similar manner. Items not removed from inventory when shipped or sold show up later on inventory documents as excess inventory.