Mori Seiki Lathe Fanuc Control Manual

Mori Seiki NMV Programming G-codes and M-codes complete lists for cnc. AI contour control II high. CNC Machine G Codes and M Codes – CNC Milling and Lathe. MANUAL GUIDE i conversational programming software lets users program a CNC without. All of the relevant information is displayed on one CNC screen. We get Fanuc macro programming manual for mori seiki DjVu, PDF, ePub. Sep 17, 2014 MORI SEIKI SL-2 CNC LATHE TURNING CENTER with FANUC.

Hello everyone, Recently a friend bought a used Mori Seiki SL3 with Fanuc 6T Controller. We started making simple programs very quickly and one day the machine just didn't move. When I turn the machine on I used to type G28 U0.0 W0.0 to move to reference point but this doesn't work anymore. The only way I can move the machine is in JOG mode or with the handwheel.

I can't run any program or MDI sequence. Has anyone any experience with this kind of problem?

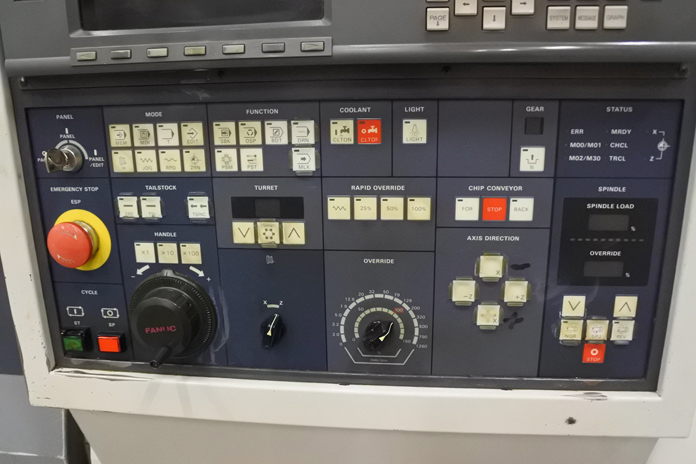

How can I know what is wrong with the machine? I have a video that shows what I'm doing and the results. Thank you very much in advance. You need to home the machine when you power on the control each time. Power on the machine and place the mode switch in the ZRN position (see the picture below, red arrow). You should be able to jog the axis in that ZRN mode, but when you get close to the home position, they will slow down as they hit the deceleration dog.

Keep pressing the jog button until the axis reaches the home position. You have to do this procedure for each axis every time you start up the machine. Check your operator manual, it probably has more specific info. That's the standard way for most Fanuc controls (and most machines in general). Hello everyone, Recently a friend bought a used Mori Seiki SL3 with Fanuc 6T Controller. We started making simple programs very quickly and one day the machine just didn't move.

When I turn the machine on I used to type G28 U0.0 W0.0 to move to reference point but this doesn't work anymore. The only way I can move the machine is in JOG mode or with the handwheel. I can't run any program or MDI sequence.

Has anyone any experience with this kind of problem? How can I know what is wrong with the machineLots of old Mori machines have the low way oil float switch tied into Feed Hold or Single block signals so the machine won't run if the oil is low. Check that first. You need to home the machine when you power on the control each time. Power on the machine and place the mode switch in the ZRN position (see the picture below, red arrow).

You should be able to jog the axis in that ZRN mode, but when you get close to the home position, they will slow down as they hit the deceleration dog. Keep pressing the jog button until the axis reaches the home position.

You have to do this procedure for each axis every time you start up the machine. Check your operator manual, it probably has more specific info. That's the standard way for most Fanuc controls (and most machines in general). Thanks for your answer!!! I tried to do this procedure when turning the machine ON. I referenced the axis the way you indicated and the leds for each axis turned on.

Yet the machine doesn't move in automatic mode. If you have a copy of the ladder, you might be able to figure it out. Is the chuck clamped? Is the lube system pressure switch working? Is the tailstock retracted? Is the edit lock switch turned to 'lock'?About these questions, The chuck IS clamped. The tailstock IS retracted.

Ge Fanuc Control Manual

Esab lah 630 service manual. The edit lock switch IS turned to 'lock'. I don't really know how to check the lube system pressure switch.

How can I do that? Also I don't have the manuals for this machine, I serchedd everywhere I could and didn't find it.