Cmg Imex Manual

A banquet manager is responsible for the quality and performance of banquet staff. This means interviewing, hiring, training and reviewing employees and. A RECIPE FOR SUCCESS BANQUET SERVER TRAINING MANUAL. Service through a focus on quality, talented staff, and easy access to decision makers. What is JOB as a Banquet Server. To provide quality. Kitchen and service staff must understand. Banquet servers are expected to be neat and well groomed. This handbook is provided in an MS-Word file to make it easier for purchasers to. The Club uses temporary catering servers to supplement its staff for catered events. While temporary. Banquet table, trash can, buspans, a tub for dumping. Banquet staff training.

. Decrease project turn-around time.

Integrating different commercial multiphase flow simulators (e.g. The Petrel software package instead of manually generated configuration files.

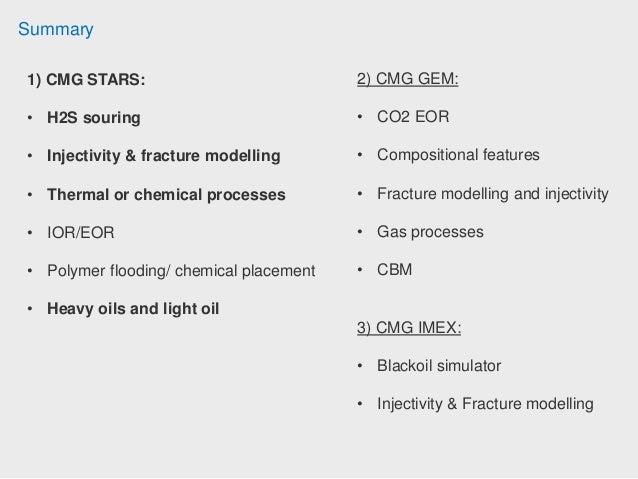

Run more simulation jobs simultaneously and get results faster than before. Additional parallelization increases parallel speed-up when jobs are submitted on a higher number of cores. Reduce capital expenditures with efficient use of current IT hardware, no annual upgrades required. Quickly load results of large models using the new standardized and compressed SR3 files to maximize productivity Want to learn more? Check out the focused on IMEX - you'll have an opportunity to learn from our customers and our R&D team on innovative applications of IMEX in the field.

Blog entries 0. Introductory remarks 1. IMEX to 2-component STARS 2.

2.1 Component Mixing 2.2 Conversion IMEX to STARS 3. Parameter Sensitivities part 1 4. New refcase: Recomputed Bo 6. Sensitivity on KV-values 7. Unexpected Saturation behavior in B-O model 12. Converting phase viscosity to component viscosity 13. STARS options for Interpolation of Rel-perm curves 14.

Simulating dynamic permeability by running a sequence of restarts, with permeability updates at each restart time based on results from STARS results files (.sr3) Also works for GEM and IMEX 15. This requires an understanding of component mixing that I didn’t have when I started (and probably still don’t have). The challenge is actually to convert the simple dead-oil description to a component mixture model. In a live oil model more and more gas is liberated from the oil as pressure decreases, so intuitively you could set up a (linear / almost linear) relationship between pressure and degree of mixing. A dead oil model is characterized by a two-regime situation: Reservoir oil is always above bubble point pressure, which means no free gas, amount of dissolved gas in the oil is constant, and doesn’t matter at all until the oil is taken to the surface, and then the liberated gas is constant (per volume). I didn’t and don’t see a straightforward and simple mixing model for this.

Using the matched IMEX-STARS data sets I was now in a position to test if thermal effects are important: Typical reservoir temperatures are in the range 70 - 140 degrees, while injection (sea) water will be 4 - 15 degrees, and hence cool down the oil when they contact. Setting up this case was actually easy in STARS.

Enthalpy models and all water behavior was taken from STARS default library. To construct temperature dependent K-values and viscosity parameters I simply used the “Selected Components”-tables from the “Tables” section at the end of the Stars User Guide, plugged in the formula in a spreadsheet, and tested the parameters from the tables until I found a set which matched the IMEX model at 72 degrees. Final tables are found in the data files. Three cases were tested: Reservoir temperatures 72 and 140 degrees, and injection water temperature 8 and 15 degrees.

Results are shown to the left, noticeable but not significant differences. Which means we can continue to run these cases isothermally without too large errors.

Cmg Imex User Manual

Grid refinement in CMG IMEX/GEM/STARS is relatively simple to define, and several levels of refinement can be defined in a logical manner. The main difference from the ECLIPSE way of doing it, is that in ECLIPSE you define the total number of refined grid blocks in the coarse box, while in CMG you define the refinement for each block. To refine blocks i=1-3, j=1, k=1 such that each coarse block is divided into 3 x 3 x 3 blocks, in ECLIPSE you’d set the total number of refined blocks (x-direction 9), while in CMG you set it to 3.

Cmg Imex Manual

The data file includes refinement for the thermal example, with syntax for one and two levels of refinement. The only changes are found in the GRID section and Well perforations. The data files were run in STARS, and results (for both one and two levels of refinement) were identical to the reference case.